Novice/Beginners Guide to Router Bits Part 2

|

To build on the previous post, some additional questions have been asked about choosing a router bit.

Router Bit Shank Size:

The shank size of the router bit can influence router bit performance.

The best material for a router bit?

To start with this is a tricky question. The material at the tip of a router bit does have bearing on how it will perform. In our case, all carbide-tipped or solid carbide router bits are C3 or C4 carbide depending on the application. We also make very limited steel-only router bits for certain markets. PCB router bits are what are referred to as diamond router bits.

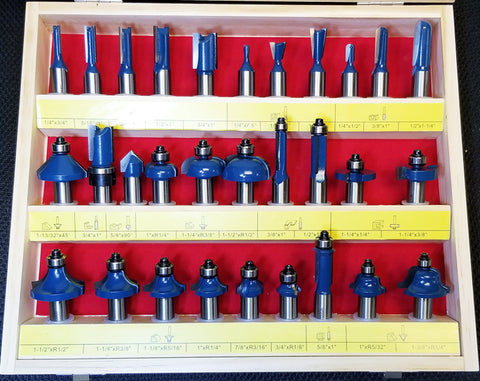

1. High-Speed Steel Router Bits are generally used in straight bits in today’s market. They are an inexpensive bit used for the repeated task. They can be used in most materials a carbide bit can be used with but tend to dull abundantly faster than carbide.

2. Carbide-tipped router bits are the most common router bit woodworkers are used to seeing. They are the best value for most woodworkers as they stay sharp longer than HSS router bits and have most of the benefits of solid carbide router bits. Carbide-tipped router bits can come in a variety of flutes and angle variations depending on the application.

3. Solid carbide router bits are typically meant for specific applications where other router bits may wear or produce less than the desired finish. Solid carbide router bits are mainly spiral in design which produces a superior cut to 2 fluted straight carbide tipped or 2 flute straight solid carbide router bits in many applications. Solid carbide router bits are a mainstay of the CNC router industry.

4. PCD (Polycrystalline Diamond) router bits are used mostly for abrasive material and not solid wood. They last longer than any other type of cutting surface. PCD cutters are mostly used in industrial applications. They are the most expensive of all router bits.

If you have an additional question on this please call 800-472-6950 or email sales@woodline.com |