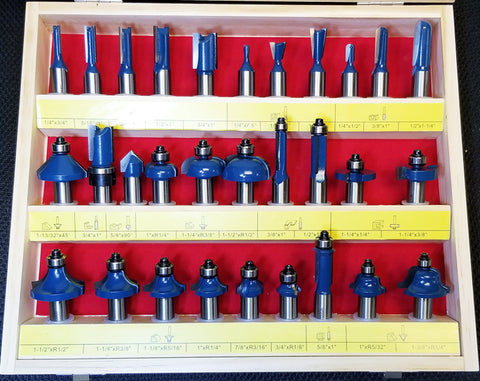

Straight Router Bits

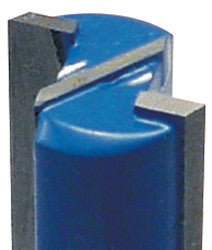

There are many decisions to make in straight router bit selection. The most popular choice is a two-flute carbide-tipped router bit. They will have less vibration and a smooth cut. A single flute is used when cut speed is more important than the finish. Fewer flutes mean improved chip clearance and faster speed. A straight router bit with shear has angled carbide flutes for a slicing rather than a chopping cut which produces a cleaner edge. If a plunge cut with a flat bottom is desired, look for the plunging straight router bits. For the ultimate in finishing, nothing beats a solid carbide spiral bit, but they can be delicate and costly.

Always select the shortest length needed for the project since the longer length can mean deflection and vibration. Never force the router bit or use a worn or damaged bit. Always use multiple passes, especially with small diameter bits. Never cut more than half the diameter of the router bit in a single pass.